Primal Herbs Expands In-House Manufacturing in Florida for Supply Chain Control

Originally published on January 28, 2026

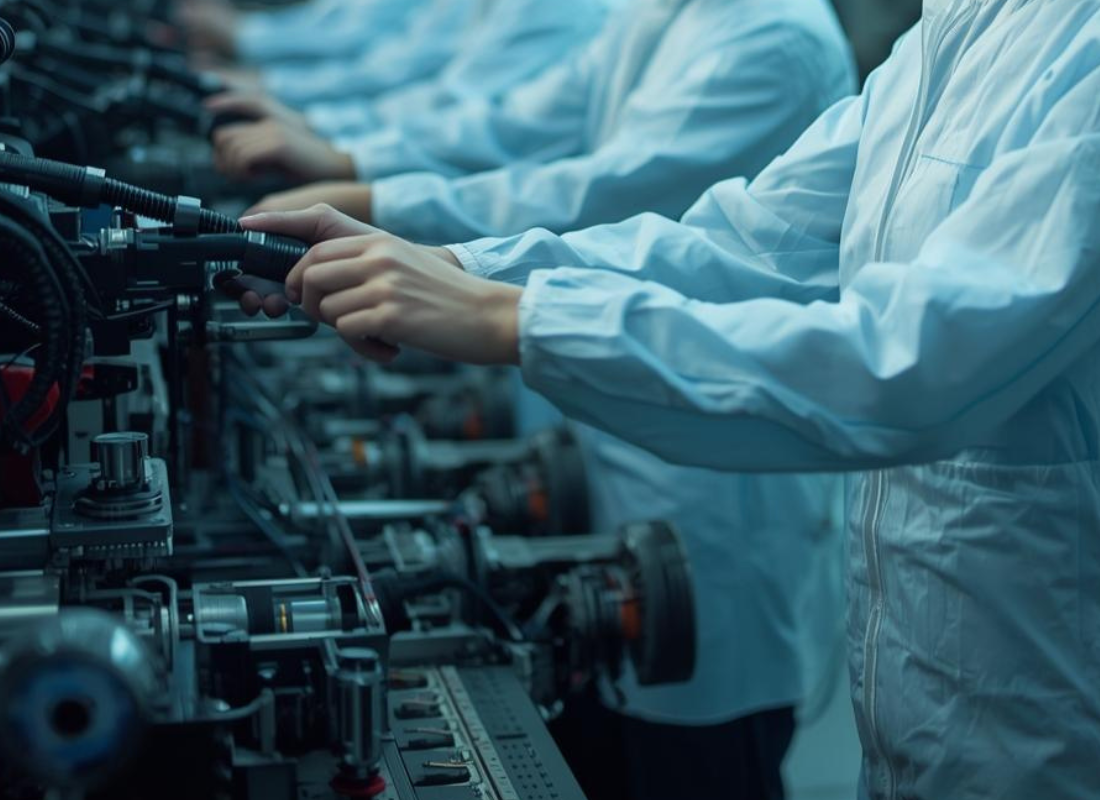

Primal Herbs has announced the expansion of its in-house manufacturing operations in Florida, marking a strategic shift toward greater supply chain control and quality oversight in the herbal supplement industry. The company’s decision to bring more production capabilities under direct management reflects growing industry concerns about supply chain reliability and product quality assurance.

The expansion by Primal Herbs represents part of a broader trend among supplement manufacturers seeking to reduce dependency on third-party contractors and establish more direct control over their production processes. By expanding manufacturing capacity within Florida, Primal Herbs aims to enhance its ability to monitor every stage of production while maintaining closer oversight of raw material sourcing and finished product quality.

Primal Herbs specializes in herbal supplements and natural health products, serving a market increasingly focused on transparency and quality assurance. The company’s move to expand in-house manufacturing capabilities positions it to better respond to consumer demands for traceable, high-quality herbal products while reducing the complexities associated with outsourced production relationships.

Why Primal Herbs Chose Florida for Manufacturing Expansion

Florida’s business environment continues to attract manufacturers across various industries, including the rapidly growing nutraceutical and supplement sector. The state offers several advantages for companies like Primal Herbs, including favorable tax policies, strategic geographic positioning for distribution, and access to key shipping infrastructure through major ports and transportation networks.

The expansion by Primal Herbs in Florida also positions the company within a state that has become increasingly attractive to businesses relocating or expanding operations from other regions. Florida’s regulatory environment and business-friendly policies have made it a destination of choice for manufacturers seeking operational efficiency and growth opportunities.

Supply Chain Accountability Drives Primal Herbs’ Strategic Decision

The decision by Primal Herbs to expand in-house manufacturing reflects broader industry challenges related to supply chain transparency and quality control. Herbal supplement manufacturers face increasing scrutiny from regulators and consumers regarding product purity, potency, and consistency, concerns that can be better addressed through direct manufacturing oversight.

By bringing more production in-house, Primal Herbs gains enhanced ability to implement quality control measures at every stage of the manufacturing process. This approach allows for real-time monitoring of production standards and immediate response to any quality issues that might arise, reducing the risk of product recalls or regulatory complications.

Implications for Florida’s Growing Nutraceutical Manufacturing Sector

The expansion by Primal Herbs contributes to Florida’s growing reputation as a hub for nutraceutical and supplement manufacturing. The state has attracted numerous companies in the health and wellness sector, creating a developing cluster of related businesses that can support each other through shared supply chains and specialized service providers.

This manufacturing expansion also signals potential opportunities for local suppliers of raw materials, packaging, logistics services, and specialized equipment used in supplement production. Companies like Primal Herbs often work with networks of regional suppliers, creating multiplier effects throughout the local manufacturing ecosystem.

Financial and Operational Considerations for Supplement Manufacturers

The move by Primal Herbs to expand in-house manufacturing capabilities involves significant financial and operational planning considerations. Manufacturers must evaluate the costs and benefits of direct production control versus outsourced manufacturing arrangements, considering factors such as capital investment requirements, operational expertise, regulatory compliance, and long-term scalability.

For supplement manufacturers considering similar strategic moves, the approach taken by Primal Herbs demonstrates how companies can leverage in-house manufacturing to differentiate their products in an increasingly competitive market. Direct manufacturing control can provide competitive advantages through improved quality assurance, faster response times to market demands, and enhanced ability to customize products for specific market segments.

Looking Ahead: Primal Herbs’ Florida Manufacturing Future

The expansion of manufacturing operations by Primal Herbs in Florida positions the company for continued growth in the evolving supplement market. As consumer preferences increasingly favor products with transparent sourcing and manufacturing processes, companies with robust in-house capabilities may gain significant competitive advantages.

The strategic decision by Primal Herbs to prioritize supply chain accountability through expanded manufacturing capabilities reflects industry-wide recognition that quality control and transparency are becoming essential differentiators in the supplement market. This expansion in Florida provides the company with a strong foundation for meeting these evolving market demands while maintaining operational flexibility for future growth.

All content provided in this article is for informational purposes only. Matters discussed in this article are subject to change. For up-to-date information on this subject please contact a James Moore professional. James Moore will not be held responsible for any claim, loss, damage or inconvenience caused as a result of any information within these pages or any information accessed through this site.

Other Posts You Might Like